The concept of Reorder Points in inventory management has evolved significantly due to advancements in technology and data analytics, transitioning from simple manual methods to sophisticated AI-driven systems. A holistic approach that integrates Reorder Point management with broader business strategies is essential. Future innovations, such as blockchain and IoT, could further refine Reorder Point calculations by enhancing supply chain transparency and real-time tracking.

Reorder Point: Calculation, Importance and Strategies

- However, the effectiveness of these tools depends on proper configuration, staff training, and the quality of input data and algorithms used.

- Examples include clothing retailers forecasting demand for specific styles and grocery chains optimising Reorder Points for perishable goods to balance stock levels and avoid spoilage.

- He has a highly informative writing style that does not sacrifice readability.

- Finally, performance monitoring with KPIs like inventory turnover rate and stockout frequency helps track the success of Reorder Point strategies.

The benefits of dynamic Reorder Points include improved inventory turnover, reduced stockouts and overstocks, better cash flow management, enhanced handling of market volatility, and increased customer satisfaction. However, challenges include the need for high-quality data, significant technology investments, change management, and balancing automation with human oversight. The manual calculation method for determining the Reorder Point uses the basic formula and historical data to calculate average daily demand, lead time, and safety stock. This straightforward approach is suitable for businesses with stable demand and simple supply chains.

Reorder point formula

The Reorder Point (ROP) is crucial not only for keeping inventory stocked but also for impacting various aspects of business operations and financial health. A well-calculated ROP minimises inventory management costs by reducing holding expenses and avoiding costly stockouts. It plays a key role in maintaining customer satisfaction by ensuring products are available when needed, thereby preventing lost sales and customer defection.

- It’s calculated based on your sales patterns and delivery timeframes to ensure a seamless supply chain and efficient delivery to your customers.

- The goal is to have new inventory arrive just as the last of the old stock is used.

- This long-term view is vital to account for seasonal variations and other fluctuating factors that can affect your sales volume.

- The formula’s utility lies in its ability to balance the risk of stockouts with the cost of holding inventory.

- Simplify your process with Intuendi and gear up for an efficient supply chain and inventory management system.

Lead Time

To determine safety stock, review your sales data for the highest demand periods and determine how much stockout risk you’re willing to tolerate. The formula’s utility lies in its ability to balance the risk of stockouts retained earnings with the cost of holding inventory. By considering both the expected demand during lead time and the safety stock, it provides a cushion against uncertainties while avoiding excessive inventory.

Although the basic ROP formula is simple, various factors can greatly impact its calculation and effectiveness. It is essential to understand these factors to accurately determine the Reorder Point and optimise inventory management. This formula ensures that sufficient inventory is available to meet demand during the lead what does rop mean in business time while providing a buffer for unexpected demand spikes or supply delays.

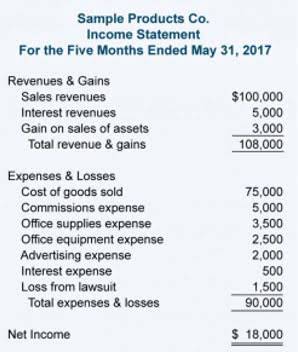

Inventory Turnover Rate

These examples demonstrate how the Reorder Point can be adapted to different scenarios, considering factors such as seasonality and variability in lead times. ○ Divide the total units by the number of days to get the average daily demand. The Reorder Point (ROP) acts as an automated trigger within an inventory management system, representing the minimum quantity of an item a business should have before https://sawtalkalem.com/archives/81545 ordering more.

The purpose of a reorder point is to find and set the lowest stock level for an inventory item at which a new order should be put in, in order to avoid a stockout. In MRP, a reorder point (ROP) is the minimum number of units of an item that a company should have in stock to avoid running out. Select the formula based on the predictability of your sales and the reliability of your type of supply chain. Formula 1 suits more stable scenarios, while Formula 2 is better for varying sales patterns.

What is a reorder point (ROP)?

- The steps include calculating average daily demand, determining lead time, setting safety stock levels, and applying the Reorder Point formula.

- However, this method may not account for complex demand patterns or supply chain variations and requires regular recalculations to stay accurate as conditions change.

- This means that the demand rate may be slightly exaggerated to alleviate the risk of a stockout.

- For many businesses, a common approach is to calculate the average usage during the lead time and add a percentage of that as a buffer.

- Excess stock ties up capital and increases holding costs, which include expenses for warehouse storage, insurance, and security.

A high turnover rate may require more frequent reordering and higher Reorder Points to meet demand, while a low turnover rate could allow for lower Reorder Points to avoid overstocking. Since turnover rates can vary between products, it’s often more effective to calculate Reorder Points individually for each product rather than applying a uniform approach across all items. The sales or manufacturing rate, or demand rate, also differs per item and is a function of consumption over time. In the above graph, the demand rate of an item is represented by the stock level’s (green line) angle. In eCommerce, where customer satisfaction hinges on the seamless availability of products, mastering inventory management is necessary. A staggering 4% of annual sales are lost on average due to stockouts, yet overstocking, while appearing as a safety net, can silently erode your profits with rising holding costs.

Lead Time in the ROP calculation refers to the time it takes from placing an order with your supplier to having the product ready for sale. In this first formula variant, Average Daily Usage is a metric that tracks the daily movement of your products. This figure is multiplied by the Average Lead Time in Days – from initiating an order to when it is received and ready for sale. This multiplication gives you the Lead Time Demand that reflects the quantity of stock that will be consumed.